From Farm To Jar: The Journey Of Private Label Peanut Butter

If you've ever wondered how private label peanut butter makes its way from the farm to your pantry, then this article is for you. The process of creating this beloved condiment is a fascinating journey that involves careful attention to detail and a commitment to producing a high-quality product. In this article, we will explore the different stages of this journey and what it takes to create peanut butter that customers love.

The Origins of Private Label Peanut Butter

Before we delve into the peanut butter production process, let's take a quick look at the origins of this delicious spread. The discovery of peanut butter is credited to Dr. John Harvey Kellogg, who patented the process of making peanut butter in 1895 for use in healthcare as a meat substitute for patients with poor teeth. However, it wasn't until the early 20th century when peanut butter was sold commercially in grocery stores.

As the popularity of peanut butter grew, so did the number of brands. The first peanut butter brands produced their own peanut butter, but as the industry grew, retailers began creating their own private label brands. Private label brands are products that are manufactured by one company but sold under another company's brand name. They have become an essential part of the food industry, and peanut butter is no exception.

Private label peanut butter has become increasingly popular in recent years, and for good reason. Retailers can offer their own unique flavors and packaging, while still maintaining a high level of quality and affordability. Plus, it allows retailers to have greater control over their supply chain and pricing.

One of the biggest advantages of private label peanut butter is the ability to offer consumers a wider variety of options. Many private label brands offer organic, natural, and even flavored peanut butter, such as honey or chocolate. This allows consumers to find a peanut butter that fits their specific dietary needs and taste preferences.

Private label peanut butter also provides retailers with a competitive edge. By offering their own brand of peanut butter, retailers can differentiate themselves from their competitors and build customer loyalty. In fact, according to a study by the Private Label Manufacturers Association, 90% of consumers say they are likely to purchase a private label product if it meets their needs.

Overall, private label peanut butter has become a staple in the food industry, offering consumers a wider variety of options and retailers a competitive edge. So the next time you're at the grocery store, be sure to check out the private label peanut butter options and see what unique flavors and packaging they have to offer.

Sourcing Quality Peanuts

The first step in creating delicious peanut butter is sourcing high-quality peanuts. The quality of the peanuts used has a significant impact on the taste and texture of the finished product, and prides itself on sourcing only the best. To ensure the quality of the peanuts, the sourcing process involves selecting the right peanut varieties and working with farms that follow sustainable and ethical farming practices.

-- Choosing the Right Peanut Varieties

There are different varieties of peanuts, and each has unique characteristics that make it suitable for specific applications. For peanut butter production, we typically use the Virginia, Spanish, and Valencia varieties. Virginia peanuts are the most commonly used variety for peanut butter production and have a more substantial kernel size compared to other varieties. Spanish peanuts are smaller and have a sweeter taste while Valencia peanuts have a slightly oilier texture.

-- Sustainable and Ethical Farming Practices

The farms that supply peanuts for peanut butter production often have to meet specific standards to ensure that the peanuts are safe for consumption and produced sustainably. This involves following strict farming guidelines, such as reducing water usage, using natural fertilizers, and integrating pest management systems. Many farms that supply peanuts for making peanut butter also encourage fair labor practices and support their local communities.

The Production Process of Private Label Peanut Butter

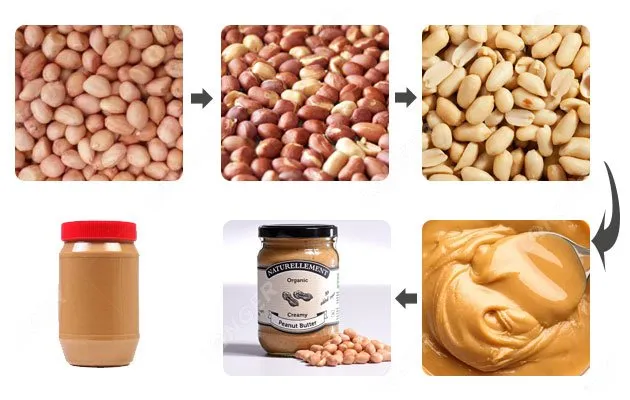

Once high-quality peanuts have been sourced, the next step is the peanut butter production process. This involves a series of stages that transform raw peanuts into smooth and creamy peanut butter.

-- Cleaning and Sorting the Peanuts

Raw peanuts undergo a thorough cleaning process to remove any dirt, debris, and foreign matter. The peanuts are then sorted to remove any damaged or substandard peanuts. This stage is critical in ensuring that the finished product meets the desired quality standards.

-- Roasting and Grinding Techniques

The peanuts are then roasted to bring out their flavor and gently break down the oils to create a smooth consistency in the final product. The roasted peanuts are then ground into a smooth paste, and different ingredients, such as sugar and salt, are added to create the desired flavor profile.

-- Adding Ingredients and Flavors

A popular trend in peanut butter production is to add different ingredients to complement the natural flavor of peanut butter. This can involve adding various types of sweeteners or flavors such as honey or chocolate. This stage is where the unique flavors of different peanut butter varieties come into play.

Quality Control and Assurance of Private Label Peanut Butter

Quality control is critical in producing high-quality peanut butter. To ensure consistency and safety, the production process undergoes several quality assurance tests, including physical and sensory evaluations. The finished product is also tested for microbiological analysis to ensure that it's safe for consumption.

-- Ensuring Consistency and Safety

Quality control measures are applied throughout the production process to ensure that the finished product meets the desired quality and safety standards. Every batch is checked for consistency in flavor, texture, and aroma. Any batch that does not meet the desired quality standards is rejected.

-- Meeting Industry Standards and Certifications

The food industry is highly regulated, and peanut butter production is no exception. Peanut butter manufacturers are required to comply with various industry regulations and certifications to ensure that their products are safe for consumption and meet high-quality standards. Examples of industry certifications include the Safe Quality Food (SQF) certification and Good Manufacturing Practices (GMP) certification.

Packaging and Labeling of Private Label Peanut Butter

Once the production process is complete, the final stage involves packaging and labeling the peanut butter. This stage is critical in ensuring that the peanut butter is protected from contamination and is attractive to the consumer.

-- Selecting the Right Jar and Lid

The packaging materials used in peanut butter production must be of high quality to ensure that the peanut butter is safe for consumption. The packaging materials used include jars and lids that are designed to protect the peanut butter from contamination, oxygen, and moisture. Careful attention is paid to the quality of the packaging to ensure that the peanut butter stays fresh and flavorful for extended periods.

-- Designing an Eye-Catching Label

The packaging design of peanut butter involves creating an eye-catching label that appeals to the customer. The label contains essential information such as ingredients, nutritional information, and allergen warnings. Peanut butter labels often feature brand colors and eye-catching graphics that make the product stand out on store shelves.

The Final Word

From farm to jar, the journey of Nutrionex private label peanut butter is a fascinating process that requires careful attention to detail and a commitment to creating a high-quality product. The production process is complex and involves numerous stages to ensure that the peanut butter meets industry standards and customer demands. By paying careful attention to each stage of the process, producers can create peanut butter that customers love and trust.